FIBC (Flexible intermediate bulk container) is the most cost-effective industrial packaging solution as compared to any other traditional method. In a constantly evolving market, FIBC jumbo bags are irreplaceable due to the neutral property of material and can be produced as per the needs of users while being light weighted. SafeFlex offers a variety of these industrial packaging-friendly big bags listed as below.

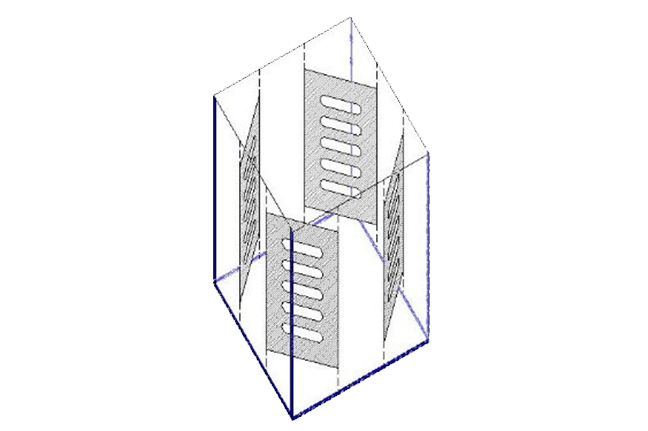

CUBE BAG, NEXT GEN FIBC

ADVANTAGES OF A CUBE BAG:

- Better Aesthetics, providing better value to your product.

- Better Dimensional stability, leading to higher stackability.

- Square/Rectangular shape after filling, leading to lower cost of handling and transport on per kg basis.

- All of the above lead to higher margins in your business.

Cube bag has all the advantages of Rigid FIBCs in terms of dimensional stability, and cost & transport advantages of a Flexible IBC. This is like having your cake and eating it too!!

Also, in comparison to conventional baffle bag, it transports 8% more material in same space available. Imagine the millions which can be saved in cost of transportation alone!

Following table gives you the comparison with a standard baffle bag.

| ATTRIBUTE | UNITS | CUBE BAG | BAFFLE |

| BAG SIZE | inches | 43.5*43.5*46 | 42X42X46 |

| FOOT PRINT | inches | 44*44 | 44X44 |

| CROSS SECTIONAL AREA IN BAG MIDDLE | Square inches | 1936 | 1936 |

| BASE CONTACT AREA | Square inches | 1892 | 1764 |

| TRANSPORT FACTOR | factor | .977 | .911 |

| UNIT PRICE | comparative | SLIGHTLY MORE | STD |

| VOLUME | CFT | 50.37 | 46.96 |

| TRANSPORT COST PER CFT | USD | LOW | STD |

EXAMPLE OF SAVINGS USING A CUBE BAG

40’ HC container inside dimensions are:

2.347×12.056×2.684 m (92.25”x474.5”x101.5”)

Such a container can take 20 bales of foot print 46”x47”. Assuming 15.5” space for 2 pallets and stacking margin, filled height of the bale can be 43” ( 43+43+15.5 = 101.5).

For a foot print of 46×47, cube bag size will be 45.5×46.5, and that of a baffle bag will be 43.5x 44.5. The cubic feet per bale will be:

Cube bag – 46.5*45.5*43/12/12/12 = 52.65

Baffle bag – 43.5*44.5*43*1.03/12/12/12 = 49.61

We have considered 3% increase capacity in baffle bag due to bulging of areas between baffles, which leads to increase in baffle bag foot print.

So for 20 bales, cube bag will transport 52.65*20 = 1053 cft and baffle bag will transport 49.61*20 = 992 cft.

Assuming 1053 cft corresponds to 44000 lbs, 992 cft will correspond to 41450 lbs, and if cost of loading, transport and unloading one container is usd 3000, cost per 1000 lbs is as under:

Cube bag – 68.18

Baffle bag – 72.38

That is a saving of usd 4.2 per 1000 lbs, meaning for a plant producing 30 Million lbs of a product every year (2×40’ container load every day), it transpires to a saving of usd 126,000.00 every year!!

So what are you waiting for, enquire it today, use it from 2 months down the line and start counting your cash!!

Our Super Stable jumbo bag has a unique round bottom construction and therefore offers great valuable advantages as compared to other Standard jumbo bags:

- Extremely stable, allows high stackability (depending upon body fabric used), saving costly ground space.

- Very competitive as compared to the conventional baffle bags.

- Occupies lower ground space with respect to standard square/rectangular base bags.

- Lower fabric expansion allows bags to be stored in racks with fixed spacing.

- Same volume in lower height with respect to standard bags.

This is a term for our circular baffle jumbo bag with no side seams. This construction offers a better stability; better sift resistance and lower costs. It is a new concept on which patent has been applied.

Advantages of Tubo Baffle Bags over Standard 4 Panel Baffle bags:

- Saves about 25 to 50 cents per bag for sift resistant bags.

- Since bag weight is lower, freight costs in importing are lower.

- Due to lesser sewing, bag safety is superior.

- Due to lesser sewing, bag sift resistant is superior and less costly.

- Due to lesser sewing, contamination issues are reduced

This product line requires a very high degree of cleanliness and every care is taken to ensure this our hygiene bags are completely safe for direct food contact packaging. Such bags are made in a clean room environment certified by the stringent norms of ISO 22000:2005 and BRC.

The entire production unit is guided by the Good Manufacturing Practices and the Company’s strong systems formulated over years of experience. Not just the use of virgin resin, every stage of the manufacturing process and inspection ensures that such products meet the highest standards in all respects. Apart from the various checkpoints, all bags pass through our high pressure cleaning and metal detection process and are packed in a Hygienic manner.

There are several products which generate static charge when they come in contact with plastic surfaces during filling, emptying or during the transportation. It is recommended to use Type C or D bags while filling such products so that there is no hazard even if the charge comes in contact with flammable products or environment.

Type C bags are made with a conductive network of Silver/Carbon yarn and carbon films that safely ground the electrostatic charge. The conductive Network dissipates all the charge to mother earth through the grounding tabs. Each and every part of each and every bag is ensured to have a grounding resistance of less than 100 Mega Ohms.

Type D bags dissipate the charge in air. This is done through micro fibres which dissipate the charge in air before it reaches any critical limit to cause shock or flaming. These bags do not require any grounding, but the operators handling these bags must protect themselves from being an easier path to static dissipation by using proper insulated footwear and hand gloves if handling any earthed part while handling these bags.

Both these bags play an important role in ensuring the safety in case of highly flammable atmospheres.

Renowned testing institutes like Shirley and Chilworth have verified the electrostatic properties of both types of these jumbo bags.

There are several products which generate static charge when they come in contact with plastic surfaces during filling, emptying or during the transportation. It is recommended to use Type C or D bags while filling such products so that there is no hazard even if the charge comes in contact with flammable products or environment.

Type D bags dissipate the charge in air. This is done through micro fibres which dissipate the charge in air before it reaches any critical limit to cause shock or flaming. These jumbo bags do not require any grounding, but the operators handling these bags must protect themselves from being an easier path to static dissipation by using proper insulated footwear and hand gloves if handling any earthed part while handling these bags.

These jumbo bags play an important role in ensuring the safety in case of highly flammable atmospheres.

Renowned testing institutes like Shirley and Chilworth have verified the electrostatic properties of both types of bags.

These are the jumbo bags made from specially woven highly breathable fabric initially designed to store peanuts as per ASTM INTERNATIONAL standards (https://www.astm.org/). These jumbo bags are used to keep the filled food product fresh and without any damage.

The fabric is generally uncoated in 6.5 oz per sq. yards or 220 gm per sq. metre with a +-3% variation. The breathability of fabric is not achieved by irregular weaving or slipping tapes, rather with a tape count of 11×12 per sq. inch.

For handling of hazardous materials, there are very stringent requirements for bag performance, which can be complied with by experience, technology, knowledge, and consistency. SafeFlex has complete in-house testing facilities for all the groups of UN bags. Be it drop test, compression test or righting test, procedures, and systems are in place. SafeFlex has been giving UN bags for all three groups and in all three varieties of un-coated, coated, and liner FIBCs.

There are thousands of chemicals bearing various properties and at SafeFlex we ensure that their properties remain intact so that the users get the deliveries in their original best form. Our chemical jumbo bags are designed keeping into consideration the different behaviours of the product being filled. Many critical parameters, not limited to, are as under:

- Fineness of the product, like 3 micron powders which flow like water are handled by use of triple dust proof construction.

- Hygroscopic materials are handled by use of liners.

- Super sensitive materials which require critical barrier properties to oxygen and other gases besides moisture are packed using barrier films made from PET, Nylon or Aluminium Foil, as needed.

- Materials to be provided with least transportation costs require different baffle designs which are developed according to specific transportation means and storage spaces.

Treated Seeds require customized designs to ensure that they do not spill out while filling and emptying and SafeFlex has mastered itself in providing very precise solutions to the World’s largest suppliers for several years now. While taking due care in branding and providing complete handling and safety instructions, our seeds bags serve the purpose to its best.

These jumbo bags need different lifting systems for filling and dispensing. It needs to be ensured that the two systems do not interfere with each others’ use. When 4 corner loops are used, 2 central loops are redundant and when 2 central loops are used, 4 corner loops are redundant. The bags need to be made to ensure non-infringing usage of these loops for best efficiency in filling and discharge.

Fertilizers are packed in bulk quantities and require a careful packaging due to the nature of their contents. These bags are made in single loop and double loop options with or without inserted / suspended liners. Normally in customized sizes ranging from 60 x 55 x 120 cms to 90x90x150 cms, fertilizer bags are designed to suit optimally for filling and safely handling 500 kg to 1250 kgs of product.

Liner blowing and fabrication is very critical in these jumbo bags as bag filling at high speeds with due safety is of prime importance.

Also, cost of packing is a substantial element in fertilizers and that is why advanced versions of these bags in roll forms etc are being made by us which virtually automate the bag filling process.

Agricultural produce: – several products like potatoes, carrots, peanuts etc need very specialized packing to keep the contents fresh for much longer period of time. At SafeFlex, we have specialized set of machinery to produce these Ventilated jumbo bags with the breath-ability best suitable for the product.

And it is just not the machinery, but the technology used with them to get the right product out from the plant, first time, every time.

Net FIBCs are ventilated jumbo bags in U+2 panel construction with the two panels in raschel fabric and the U-panel in 13-stripped ventilated fabric. Like the ventilated bulk bags, these jumbo bags are also used for storing grains, potatoes, onions, beans, nuts and wood logs.

Mineral bags are another segment wherein the requirement is generally in bulk quantities and used for filling and transporting minerals directly from mines to the various refining divisions. Our robust FIBCs are custom designed depending on nature of the product filled like UN bags for hazardous product handling made as per the legislation governing the packaging, transportation and storage of such goods; very tough and rugged bags for sharp edged materials, hood loop bags for ease of filling etc.

For filling in bulk construction materials like sand, gravels, cement-concrete mix, soil, debris etc. our builder bulk bags are available in sizes ranging from 85 x 85 x 85 cm to 90 x 90 x 90 cm for 1000 kg and 90 x 90 x 110 cm for 1500 kg in single trip and multi trip options. Used repeatedly by renowned builder merchants, SafeFlex builder bags are designed for tough, durable and hassle-free performance, yet are inexpensive.

Asbestos is a hazardous material and appropriate care must be taken in handling any material which contains asbestos. Asbestos waste is classifiable as chemical waste under the Waste Disposal (Chemical Waste) (General) Regulation and its handling, collection, transportation and disposal is controlled by the legislation.

At SafeFlex, we take due care in manufacturing and appropriately labelling the packaging product such that it complies the applicable norms and ensures the handling, transport and disposal is completely safe and hassle free. Available for packing 1000 kgs to small truck to full 20 MT load of Asbestos waste.

–PVC, EVOH, PET, Nylon and aluminium foil are popular materials in combination with LDPE to provide different kind of barrier properties. The material to be used depends upon material being packed, longevity of packing and atmospheric conditions. Let us know the details and we can suggest most cost-efficient solution.

–Conductive carbon is carefully extruded on 3-layer co-extrusion machine to achieve the desired properties of conductivity for type C bags, which are always grounded while filling and discharging. These liners can be converted to desired shape for one, two or 4 loop bags.

–Normally, products are filled in FIBCs after they achieve ambient temperature. However, certain process needs necessitate that products are filled in the bags at temperatures up to 120 degrees, for which special materials and processes are followed wherein liner can sustain 120 degrees up to 30 mins, which is normally sufficient as the product cools down during this period.

–We co-extrude the best liners duly understanding their importance in an FIBC from 40 microns to 200 microns. All further operations like form fitting, side flanging, tabbing, bottom sealing, Suspension, Spray Gluing are done at ease on our dedicated lines that have been doing it for years with flawless perfection.

When special applications demand, we buy barrier films from reputed sources to the specifications needed and then fabricate the liners from these films and install them in the bags in the desired way.

Installing the liners in the bags is an art perfected at SafeFlex. Liner twisting, liner leaking or liner torn while packing are issues not happening any more as the reasons for such happenings have been eliminated by systematic corrective actions, the backbone of ISO systems.

All sizes and options, consistent fabric width, 4 colour prints on roll to roll printing machines, latest process control and weaving machines provide very consistent high-quality bags. Proper sewing and baling give flat packed bags which allows you to print them at your end also. Full range is the key to our services.

| Attribute | Unit | Range |

| width | cm | 12-300 |

| inches | 5-160 | |

| Weight | gsm | 35-350 |

| Oz/sq. yd | 1-10 | |

| Colours | all | |

| Lamination | gsm | 10-60 |

| Oz/sq yd | 0.3-1 | |

| Stitching | Top | Hemmed, Heat cut, cold cut, zigzag |

| Bottom | Sfss/sfds/dfds/dfss | |

| Liner | material | LDPE/HMHDPE |

| fixing | Loose, sewn, hemmed | |

| Printing | 4 colours | |

| Type of bags | Sheets, bags, box bags, pallet covers | |

| Fabric strength | Max 1.1 kg per gsm in 5 cm strip |