FIBCs/Jumbo Bags/Bulk Bags are occasionally filled with materials that reach high temperatures during manufacture and packing. Because of this, before using FIBCs in your manufacturing and shipping regiments, it is valuable to know how high-temperature products affect them. That way, you will know what to expect and how to safely follow the proper procedures when filling bags with these products.

Resources

- Home /

- Resources

FIBC

Most of the FIBCs are made by weaving polypropylene fabric. Process requires stretching of polymers at elevated temperatures to give tensile strength. If filling material increases the temperature of Pp fabric close to these temperatures, there can be temporary or permanent loss of mechanical properties of PP fabric leading to bag failures in handling.

The potential for bag damage at high temperatures finds its most critical point at around 200°F/95°C. You can use normal FIBCs/bulk bags at these temperatures, but to ensure you reap all the benefits of your FIBCs, it’s best to follow the below procedures when doing so.

- Proper Support

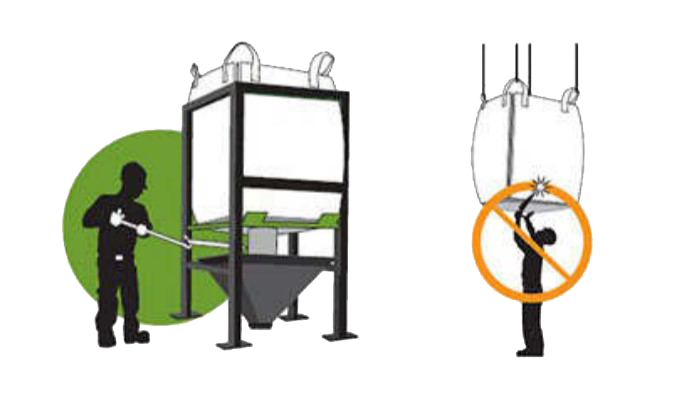

Support any bulk bag containing high-temp granules from the bottom at all times. Do not lift it using any means other than foundational support. Wait until the fabric’s surface temperature has dropped under 120°F/ 50°C before using any other method except lifting from base support like pallet.

- Check Structural Integrity

If your company fills an FIBC/Jumbo Bag/ bulk bag with a product that is over 200°F/95°C, test the bag afterward to ensure the fabric has remained uncompromised.

- Pay Attention to Temperatures

Be sure to think about the peak temperature, amount of exposure time and level of material stress on the bulk bag before you determine its future performance and structural integrity. If ambient temperatures are also high, and surface temperature odes not drop to less than 120°F/ 50°C within 4 hours, there could be permanent creep and it is best advisable to use High temperature Bags.

- Indicate Bags for Higher-Temperature Materials

If you consistently ship materials that reach higher temperatures, ask SafeFlex for a bag so suitable. FIBC/Jumbo Bag/Bulk Bag suitable for filling temperatures upto 300°F/150°C can be made and used with a set of instructions provided.

- Always Test Your Bags

If you don’t test your bags, it could lead to a break and could compromise the material being transported. You will then have to pay to repackage the material, increasing time, material, and labor costs to get the project back on track.

- Immediately Replace Compromised Bags

Replacing a bag immediately after you notice an issue will save you in the long run. It will help prevent accidents that could cost you much more than replacing one FIBC/Jumbo Bag/Bulk Bag

- Consider Specialty High-Temperature FIBCs

There are special bags available that are meant to carry high- temperature materials. SafeFlex has FIBCs/Jumbo bags/Bulk Bags which can be filled with materials as hot as 150°C/300°F . Standard PP bulk bags can get the job done for materials coming in at 50°C/120°F , but a high-temperature bag would be more reliable if you transport these types of materials often.

It’s a natural question. Can FIBCs/ bulk bags/ Jumbo bags be stored outside? If you’re going to use them for your business, it can be important to know if they can be stored outside. You use FIBCs/Bulk Bags/ Jumbo bags for packing/storage/transport of your goods, which is a smart choice. But part of that choice involves knowing the proper method for storing bulk bags so they will be fully effective when needed. If you’ve been wondering how to store bulk bags outside or about other aspects of bulk bag care, read on.

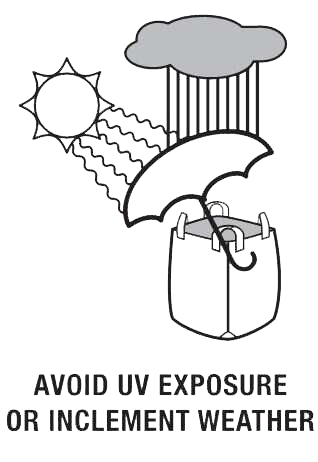

It is critical that you store your FIBC bulk bags properly. Bulk bags can stand up to heavy loads and industrial transportation, but only if they are stored properly and protected from any potential damage before use. For this reason, it is important to be aware that it is not recommended that you store bulk bags outside. The main reason for this is to protect your flexible intermediate bulk containers (FIBCs) from sunlight, or more specifically, from ultraviolet radiation. Prolonged exposure to UV rays will weaken the strength of an FIBC, making it more likely to break when loaded with goods and/or transported. The easiest way to protect your FIBC bulk bags from ultraviolet radiation is to keep them out of the sun at all times when not in use.

In addition, while you can transport FIBC bulk bags in adverse conditions, continued exposure to inclement weather, such as leaving them out in the cold, rain or snow for days or weeks at a time, can also dramatically weaken the strength of your bags.

Can bulk bags be stored outside if you absolutely have no other choice? If you do so, it will be at your own risk, and there is no guarantee that your bags will perform at the level you can normally expect from FIBC bulk bags. However, if you do store them outside, you must cover them with some material that will protect them from UV rays. If you do not, there is a much lower chance they will perform up to standards. If you are storing them outside in a place where they may be subject to adverse weather conditions, you must find a way to protect them from weather where you are storing them as well.

Even if you are storing your bulk bags inside, you must protect them for maximum effectiveness. Store them in a safe, clean facility out of the way of any direct sunlight exposure or anywhere moisture might develop. Cover them to protect them from dirt and dust as well. IN CASE IT IS UNAVOIDABLE TO STORE FILLED FIBCS/ BULK BAGS/ JUMBO BAGS IN OPEN, ask SafeFlex International Ltd, the experts there will design a bag specifically to the adverse conditions specified and give you slightly expensive but best value for money alternative so that you do not lose your sleep on bag and product safety. Contact safeflex on +91-8602007353, mail on export@safeflex.org or whatsapp on +91-7665621123.

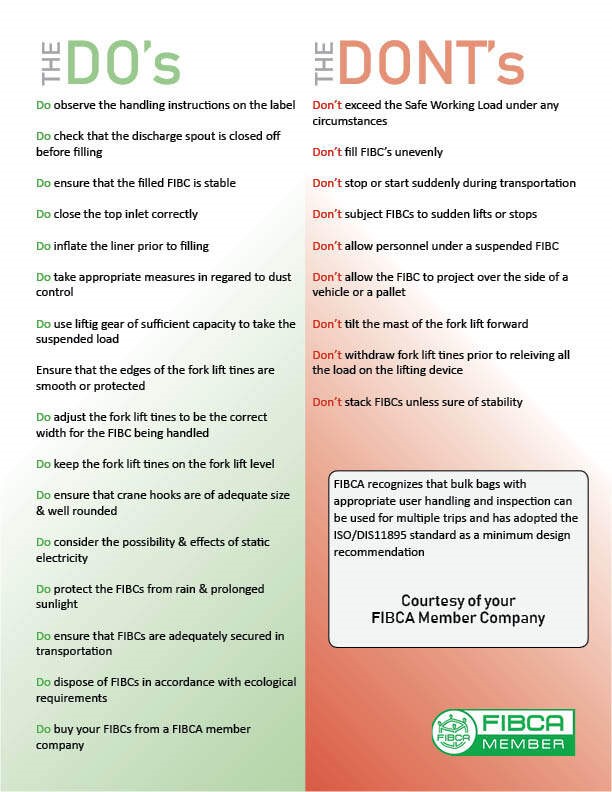

This information has been provided by the Flexible Intermediate Bulk Container Association. The latest version of The FIBCA Safe Handling Guidelines are available on their website or in this downloadable PDF.

Empty FIBCs and liners should be kept clean and stored undercover in such a manner that accidental damage, exposure to sunlight and extreme climatic conditions are avoided. Additionally, FIBCA has provided an informational video on storage and transportation of FIBCs.

FIBCs are preferably filled with the base of the bag supported by the ground or pallet, and the body of the bag supported by the top lift device.

If the FIBC has a discharge spout, it should be tied off or closed before filling. FIBCA offers an informational video on filling and emptying of FIBCs.

When filled, the ratio of the height of the bag to the width/diameter of the bag should not be more than 2:1. Stability of bags may be improved by vibration during or after filling.

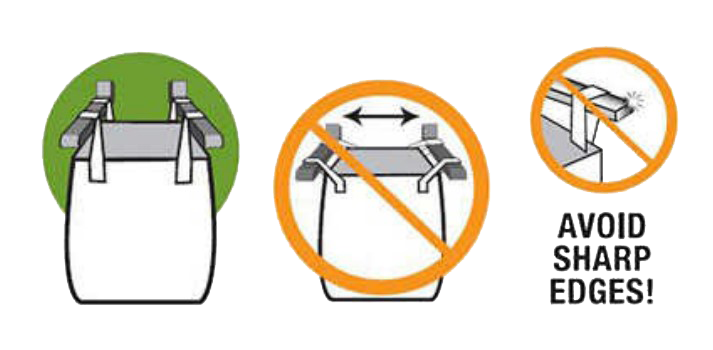

When lifting FIBCs with a fork lift truck, be sure the fork lift tines are spaced correctly. All lifting loops, sleeves, or other lifting devices should be vertical, so no damaging lateral forces will be created. Be sure the lifting loops are not twisted.

Fork-lift tines should have rounded edges and/or protective covers. Do ensure the crane hooks, bars or fork-lift arms used for lifting are of adequate size and are rounded to at least the thickness of the sling, belt or rope suspension, with a minimum radius of 5 mm.

For more questions on lifting FIBCs safely with forklifts, cranes or hoists, please refer to the following video from FIBCA:

The fork lift truck must be suitable for the load to be carried. When traveling with a FIBC hanging from the fork lift tines, there is a danger of the truck becoming unstable. The FIBC should be held close to the mast and as low as possible with the mast tilted slightly backwards. Make sure the FIBC body will not be damaged by the wheels of the truck. The load should not restrict the view of the driver.

FIBCs must not be dragged. The truck should be brought to a stop before the FIBC is raised or lowered.

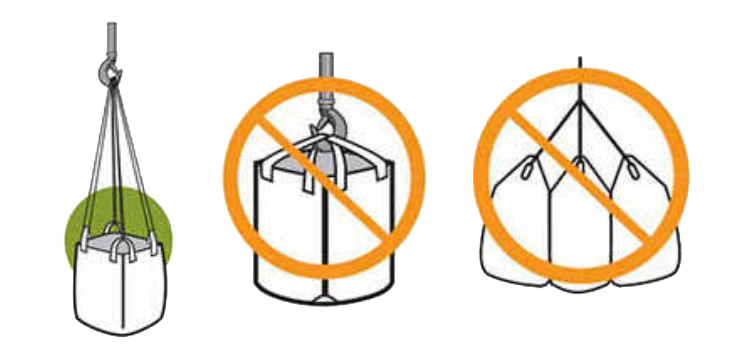

The hooks, spreader bars or other devices used for lifting, should have rounded edges and/or protective covers. FIBCA recommends the use of safety hooks with an integrated latch to prevent the hook from accidentally slipping off the loop. Hooks should have a sufficiently large radius to prevent squeezing the loop.

When the FIBC is suspended, the loops must be vertical, without any twists or knots.

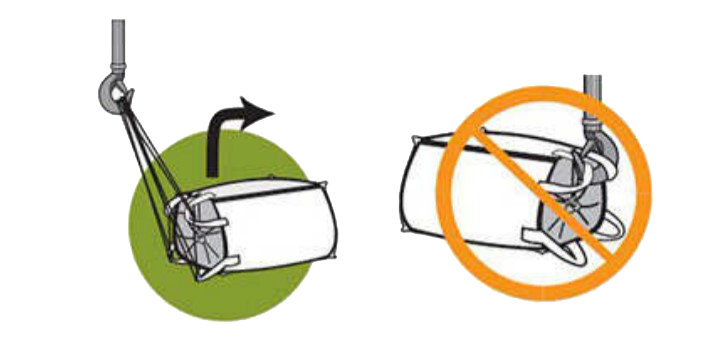

To right an FIBC that has toppled on its side, an endless fabric sling, wound through all the lifting loops, should be used. Any attempt to lift the FIBC using fewer loops than those provided, may result in the loops being torn off.

FIBCs are usually emptied by gravity but can also be emptied by suction. When emptying by gravity through a bottom discharge spout, the rate of discharge can be controlled by restricting the outlet. Flow can be stopped by lowering the FIBC onto the discharged load.

FIBCs with a plain/solid bottom can be emptied by cutting the base of the bag. Again, the flow can be stopped by lowering the bag onto the discharged load. Do NOT stand under an FIBC during discharge.

A bottom discharge spout should be opened only when the FIBC is suspended over a safety support that will prevent injury to the operator in the event of a failure of the lifting device.

Under no circumstances should anyone stand underneath a suspended FIBC; or place their arm beneath an unsupported FIBC.

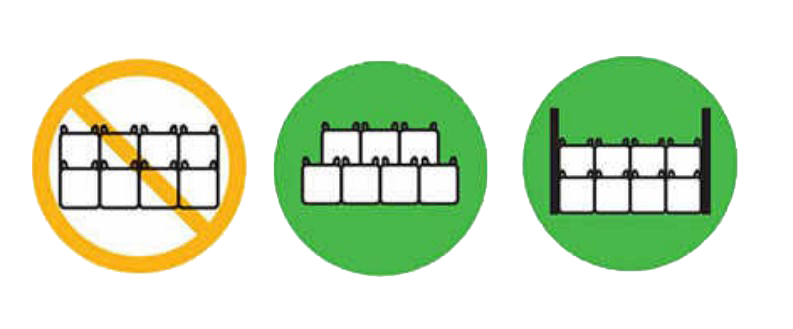

When stacking filled FIBCs 2 or more high, every effort should be made to ensure that the stack is stable. Where possible, the stack should be formed against the least 2 retaining walls, preferably 3, to achieve maximum stability. Generally, the higher the stack, the greater the number of retaining walls required.

Where only free stacking is possible, a pyramid method should be used.

FIBCs should not be pushed into a stack as this can cause damage to the sides or back of the FIBC.

If FIBCS are stored outside, attention should be paid to the top closure. Be sure the top closure is properly tied off. FIBCs should be covered with waterproof, U.V. protected material to avoid water collecting on the top of the FIBC and to prevent damage from sunlight.

Be sure that FIBCs are not standing in water.

Special care should be taken when handling bags with UN or DOT regulated materials. For questions concerning the material, refer to the supplier’s MSDS. Questions concerning FIBCs should be referred to you FIBCA member supplier.

If FIBCs are to be filled or emptied in flammable or explosive atmospheres, special features such as anti-stat material should be utilized. Your FIBCA member supplier can make recommendations for use in these areas.

The Flexible Intermediate Bulk Containers (FIBCs) are also known as Jumbo Bags, Big bags, Bulk Bag, totes, depending on the heritage and location of use of the product. Everything amounts to one thing, that is the product, which is used to pack anything from dust to diamonds, milk powder to dynamite, ores to medicines, etc. in bulk quantities which can range from 500 Kgs to over 2000 Kgs.

Depending on what kind of material you want to fill in, the bag size and material would change depending on various parameters such as environment conditions of filling, the size of material, duration of storage, conditions of storage, etc.

These jumbo bags are used to reduce your time and effort in transporting or filling your product for the next processes. It becomes of utmost importance that the packaging that you use for your precious product meets those kinds of required quality standards.

Some ways and means to ensure that you are looking at a suitable supplier is to look for a supplier who has BRC certification for its entire manufacturing facility, i.e. right from incoming of raw material (Plastic granules) to dispatch from the same premises.

Understand that static charge is created through rubbing of two materials, for eg. Glass and wool cloth. This rubbing causes transfer of electrons and after a certain threshold is reached, the charge barrier breaks and it causes you to feel that static current. Such an environment can become very dangerous when one is filling the jumbo bags which do not cover this aspect. The environment around filling station could become electrically charged and cause damage to material that is being filled. Usually the material that is being filled is flammable and even slight increase in temperature could cause them to catch fire, which can happen because of electrical discharge around material.

Such accidental incidents are easily avoidable if one uses right kind of FIBC. This would be either Type C or Type D. There is no bulk bag according to IEC standards which claims that a tote bag could be both Type C and Type D, also known as Type E (There is no official recognition for such bags).

The functionality of Type C Big bag is very different from Type D Big bag. Type C FIBCs are used for conductive properties of electrical charge, they pass the charge to the ground through its conductive tapes, which are meticulously placed while making these Bulk bags. It is very important to check each and every tote for such conductive tests, before passing on the same to you.

Type D FIBCs are used in areas where the electrical charge needs to be dissipated into environment as storing the charge or passing of the charge to the ground can be very risky. These require jumbo bags to be made from very special material and also for the manufacturer to have good knowledge about it. Such bags ensure the safety to utmost level and are highly recommended for riskier sites.

We at SafeFlex International Limited, do our due diligence in order to make sure that YOU!! get the right kind of Jumbo bag for your specialised needs. Enquire with SafeFlex International Limited to get satisfied today.

Well, as most of the questions can be answered with statement: it depends, the same goes here. If you are considering any material which has temperature less than 140 °C, yes it is possible to pack that kind of material. Kindly do specify your needs before enquiring. As a general rule, all the manufacturers assume that bag filling will take place normal conditions, such as any temperature between 15-45 °C. For any other kind of temperature conditions and material that is being filled, as it might change the property of jumbo bag. These bags might require some special kind of liner to meet your safety demands, so be sure to ask before you buy!!

Trust SafeFlex International Ltd For All Your FIBC Needs

We are the global experts on FIBCs/Bulk Bags/jumbo Bags. Come see what customers around the world have known for over 15 years – SafeFlex Reliability and Passion. You have a problem, we have a solution. Contact us on +91-8602007353 or mail to export@safeflex.org or whatsapp on +91 76656 21123